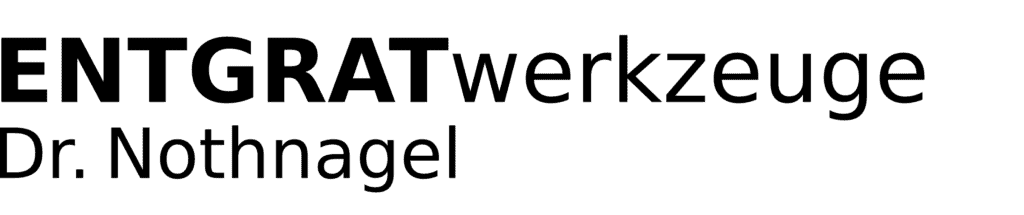

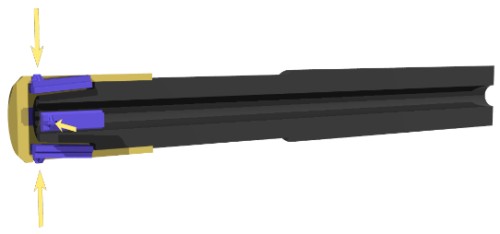

The HSD deburring tool is moved (in rapid feed) to the starting position. The cutting edges are folded in. There is no need of pressure yet. The starting position is reached when the cutting edges are in front of the burr.

HSD - High Speed Deburring for cross holes

Technology of our Deburring Tools

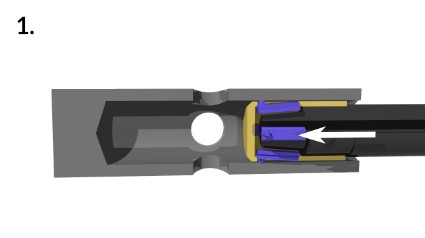

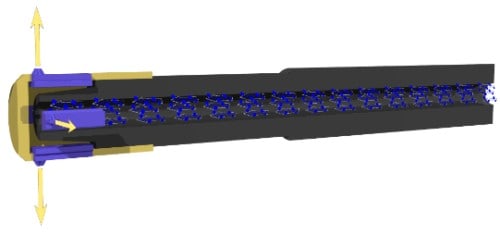

Now the deburring process begins. The coolant or air pressure is now switched on at latest. This controls the force on the cutting edges. The tool is now feeding forward in a rotating direction.

During the forward feed and rotation, the hole or intersection is deburred. The blades fold out within the intersection and are folded in again at the shape of the main hole.

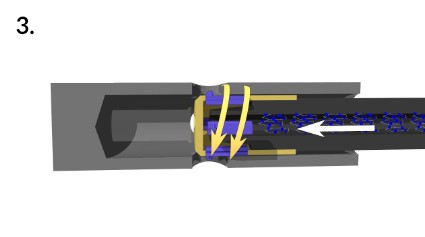

The hole has been completely passed in forward direction. Now the direction of rotation is reversed and the feed is going backwards. In the retreat, the opposite side of the intersection is now deburred. When the cutting edges have completely passed the hole, the deburring process is complete. The tool can be moved out (in rapid feed).

Pressure controlled cutting

A key feature of HSD technology are the pressure-controlled cutting edges. The pressure is applied to the cutting edges through the tool shank. Coolants, water, air or oil are suitable media. When there is no pressure, there is no force on the cutting edges, so the cutting edges snap in without any applied force.

Parameters

When pressure is applied, the cutting edges are pressed out of the shaft. The pressure height determines the force at which the cutting edges are pressed in again, which force is applied when deburring. The pressure is an essential parameter for adapting the process to the burr, the material and the edge pressure generated by the deburring. The process is furthermore controlled by rotation and feed.

Tools and Variants

Deburring cross holes and intersections

HSD deburring tools are used in many applications for deburring intersecting holes. They are available in different versions for this application. The optional functions and design features used to implement the tools depend on the requirements of the customer. We advise the necessary features and explain the possibilities.

HSD deburring tools can be made very long and slim. They are therefore very well suited for deburring cross holes in deep holes. It is an advantage that cross bores with different diameters are deburred through the main bore with one tool.

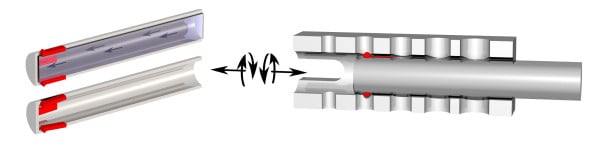

Multi-edge deburring tools

HSD deburring tools can be made very compact due to their design and the complete absence of spring-like elements. This means that not only very long and slim tools are possible, but also the arrangement of several cutting edges in one plane. With the multi-bladed tools, higher feeds are driven and machining time is saved.

The cutting edges of HSD tools can also be arranged on several levels. Several intersecting holes or other intersections are deburred in one step with one tool.

Deburring tools for stepped bores

Multi-bladed HSD deburring tools are used in stepped bores. For different diameters of the main bore stepped designed tools are in application. The different cross bores in a component with a stepped main bore can be deburred simultaneously and with just one tool. The geometry of the cross holes can be different.

Special designs and combinations

Another version is used when no coolant or pressure medium is available. Then the cutting force can be applied by an elastomer instead of the pressure. The pressure supply is not necessary.

HSD deburring tools also solve other special deburring tasks. For example, HSD tools for deburring slotted shaft ends have been in use for a long time. With these special tools, cutting edges are arranged both inside and outside. In this way, the shaft end is completely and simultaneously deburred on the inside and outside.

Use in the deburring station or machine

Frequently asked Questions

Removing burrs from chipping processes: drilling, milling, reaming, …

Materials: Steel, cast iron, aluminum, brass, …

Typical workpieces are shafts with oil drillings (gearshaft, crankshaft, camshafts, …) machine or motor housing, mechanical bearings, pneumatic and hydraulic parts.

Typical applications are crossing bore holes. Especially intersections of deep hole drillings and several also different crossing oil bores are deburred by HSD tools. Applications of one tool for different intersections are possible. Combinations of different HSD tools in one combined tool for stepped main holes are possible (ref. also special HSD tools).

Deburring at drill entry and exit, particularly non-flat, stepped, curved intersections.

High speed deburring tools are made for highly automated processes. Therefore this HSD tools are used for high quantity or mass production, short cycle times, short deburring times, reliable repeatability of the result and rationalisation of the deburring process.

The installation of deburring tools is in practice in milling, turning and other CNC machines – to take an advantage on the machine where the burr is produced. Other applications are by deburring stations and robots in post-processing.

Machines should have left- and righthand rotation, pressure supply at the deburring tool similiar to internal coolant by coolant fluid, water, oil, air (application without pressure ref. special HSD tools).

Cutting edges of HSD tools are mobile to follow contours and compensate tolerances. There are no spring or spring-like elements. The cutting edges and the force is controlled by pressure. During operation the tool is rotating and the cutting edges are passing the intersections in left- or right-hand rotation.

The HSD tool is producing a chamfer. The characteristic of the chamfer is controlled by pressure, rotation and feed.

HSD deburring tools are available and in practice starting in the diameter range from 2 mm. There are no restrictions for larger diameters. Cross holes are deburred up from approximately one millimeter. The tool length is adapted to the needs of the customer. Very slim tools with a ratio of diameter to length of 0.012 have been used for deep hole drilling for years.

HSD deburring tools in frequently needed diameters and lengths are on stock. There is no catalog, because the tools are tailor-made to the requirements in various designs and with numerous options. After the deburring task has been described, the tool is designed to fit to the application.

The HSD principle can be applied to various deburring tasks. Variants and combinations of several tools and functions are possible in one tool. The HSD technology can also be implemented without the pressure-controlled function, then there is no internal cooling or pressure media necessary.

Combining HSD Tools

In combined HSD deburring tools, several cutting edges are arranged on different levels. Different diameters can also be combined. This means that all cross holes in deep holes or stepped holes are deburred with one tool in one step.

HSD tools without pressure control

If there is no pressure medium available on the machine, the cutting force can be applied by means of an elastomer core in the tool. “Dry machining” without coolant is possible with this variant.

Special HSD variants

Some examples: Variants for the application of HSD technology are used for deburring slotted pipe ends. Deburring is done inside and outside at the same time. Another variant is used for robotic deburring. The tool heads are designed to compensate expected higher tolerances in positioning. Different cutting edges are used for HSD tools. Among other things, cuttings with a large range of action are used for deburring hole intersections inside undercuts.

We advise our customers on the possible applications. After an analysis of the task, the optimal HSD tool is designed.

Analysis, Consultation

HSD tools are designed to fit the customer’s requirements. Basic information must be available first. Basic information concerns the burr:

- the geometry of the workpiece and the location of the burr,

- the pre-processes that create the burr

- the material of the workpiece.

Other requirements as:

- quality of the surface,

- dimension of the chamfer,

- possibilities to reach the burr,

- cycle time in application.

Implementation:

- Maschine (type, equipment,…),

- available pressure and media,

- relevant post-processes.

This is the basis, we analyze and recommend.

Concept, Design and Quotation

After the analysis, the tool is designed for use. For the various requirements, the required tool properties out of the proven solutions are combined. An HSD standard tool can be the right for the tasks or a new special solution for more complex applications can be developed.

Practice

We make the HSD tool – the design and manufacturing. We will accompany the introduction in the production process when the working parameters will be tuned in detail.

"The HSD deburring tools are tailor-made precisely to the customer's requirements"

Dr.-Ing. Reinhard Nothnagel

Company owner & managing director

Inquiry - Analysis - Advice - Order

The HSD deburring tools are special tools that are individually adapted and manufactured to the component to be deburred and the process.

The following information will be very helpful in advance:

- Component drawing, sketch or photo of the location of the burrs to be removed

- Short hint on the origin of the burr, machining sequence

- Are there requirements for the chamfer or roughness after deburring?

- Is a cooling medium or compressed air available? What pressure is on or can be set?